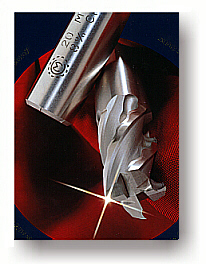

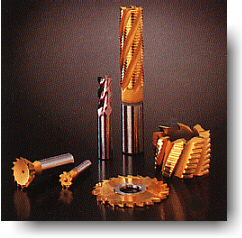

CM is proud to present the UNI-LINE®, the new conception of a futuristic end-mill for a wide application-range, developed to improve the actual large production's programme. The UNI-LINE® has been introduced through a particular concept of a sinuousoidal helix.

When the cutting edge starts working on the sinuousoidal blade meets an unless resistance to the penetration and further rating creates shearing-efforts on the opponent direction and therefore generating a more quick heat-dispersion and total elimination of cyclical vibrations.

With the UNI-LINE® we obtain:

The benefit/ advantage of CM UNI-LINE® End-mill could be used for Slotting Operation with the Depth of Cut = 1.5 x Diameter End-mill.

Compare to conventional end mill, with UNI-LINE® speed and feed should be possible increased up to 20 to 30%.

With the TiCN coated, the speed can be increased up to 30 to 40%, compare to the uncoated UNI-LINE®.

Standard Series - HSSCo 8% M42

| Code M42 8% Co. | Code TiCN | Dia. (j14) | Lt | LT | Shank dia.(h6) | Z |

| UNIMI120 | UNIMI122 | 12 | 26 | 83 | 12 | 3 |

| UNIMI160 | UNIMI162 | 16 | 32 | 92 | 16 | 4 |

| UNIMI200 | UNIMI202 | 20 | 38 | 104 | 16 | 4 |

| UNIMI250 | UNIMI252 | 25 | 45 | 121 | 25 | 5 |

| UNIMI300 | UNIMI302 | 30 | 45 | 121 | 25 | 6 |

| Code M42 8% Co. | Code TiCN | Dia. (j14) | Lt | LT | Shank dia.(h6) | Z |

| UNISL120 | UNISL122 | 12 | 53 | 110 | 12 | 3 |

| UNISL160 | UNISL162 | 16 | 63 | 123 | 16 | 4 |

| UNISL200 | UNISL202 | 20 | 75 | 141 | 16 | 4 |

| UNISL250 | UNISL252 | 25 | 90 | 166 | 25 | 5 |

| UNISL300 | UNISL302 | 30 | 90 | 166 | 25 | 6 |

Standard Series - HSSCo 8% M42

| Code M42 8% Co. | Code TiCN | Dia. (j14) | Lt | LT | CM | Z |

| UNICO160 | UNICO162 | 16 | 32 | 117 | 2 | 4 |

| UNICO200 | UNICO202 | 20 | 38 | 123 | 2 | 4 |

| UNICO250 | UNICO252 | 25 | 45 | 147 | 3 | 5 |

| UNICO300 | UNICO302 | 30 | 45 | 147 | 3 | 5 |

| UNICO350 | UNICO352 | 35 | 53 | 178 | 4 | 6 |

| UNICO400 | UNICO402 | 40 | 63 | 188 | 4 | 6 |

| Code M42 8% Co. | Code TiCN | Dia. (j14) | Lt | LT | CM | Z |

| UNICL160 | UNICL162 | 16 | 63 | 148 | 2 | 4 |

| UNICL200 | UNICL202 | 20 | 75 | 177 | 3 | 4 |

| UNICL250 | UNICL252 | 25 | 90 | 192 | 3 | 5 |

| UNICL300 | UNICL302 | 30 | 90 | 192 | 3 | 5 |

| UNICL350 | UNICL352 | 35 | 106 | 231 | 4 | 6 |

| UNICL400 | UNICL402 | 40 | 125 | 250 | 4 | 6 |

| Code M42 8% Co. | Code TiCN | Dia. (j16) | S(j16) | Hole dia.(H7) | Z |

| UNIFO401 | UNIFO402 | 40 | 32 | 16 | 8 |

| UNIFO501 | UNIFO502 | 50 | 36 | 22 | 8 |

| UNIFO631 | UNIFO632 | 63 | 40 | 27 | 8 |

| Code | Angle | Dia. | Dia. min. | Screw dia. | Total length | Shank dia.(h6) |

| 51209001 | 90 | 6.3 | 1.50 | 3MA | 44 | 6 |

| 51209002 | 90 | 8.3 | 2 | 4MA | 52 | 6 |

| 51209003 | 90 | 10.4 | 2.5 | 5MA | 52 | 6 |

| 51209004 | 90 | 12.4 | 3 | 6MA | 52 | 10 |

| 51209005 | 90 | 16.5 | 4 | 8MA | 60 | 10 |

| 51209006 | 90 | 20.5 | 4 | 10MA | 68 | 10 |

| 51209007 | 90 | 25 | 5 | 12MA | 84 | 12 |

| 51209008 | 90 | 28 | 6 | 14MA | 90 | 16 |

| 51209009 | 90 | 31.5 | 6 | 16MA | 90 | 16 |

| Code | Angle | Dia. | Total length | Shank dia.(h6) |

| 51006001 | 60 | 12.5 | 63.00 | 10 |

| 51006002 | 60 | 16 | 66 | 10 |

| 51006003 | 60 | 20 | 75 | 10 |

| 51006004 | 60 | 25 | 93 | 12 |

| 51006005 | 60 | 31.5 | 101 | 16 |

| 51009001 | 90 | 12.5 | 52 | 10 |

| 51009002 | 90 | 16 | 60 | 10 |

| 51009003 | 90 | 20 | 68 | 10 |

| 51009004 | 90 | 25 | 84 | 12 |

| 51009005 | 90 | 31.5 | 90 | 16 |

| Code | Screw dia. | Dia.(H8) | Guide dia.(f8) | Pilot length | Total length | Shank dia.(h6) | Flutes (z) |

| 59000301 | 3MA | 5.9 | 3.2 | 14 | 71 | 6 | 3 |

| 59000401 | 4MA | 7.4 | 4.3 | 14 | 71 | 8 | 3 |

| 59000501 | 5MA | 9.4 | 5.3 | 18 | 80 | 10 | 3 |

| 59000601 | 6MA | 10.4 | 6.4 | 18 | 80 | 10 | 3 |

| 59000801 | 8MA | 13.5 | 8.4 | 22 | 100 | 12 | 3 |

| 59001001 | 10MA | 16.5 | 10.5 | 25 | 120 | 12 | 3 |

| 59001201 | 12MA | 19 | 13 | 25 | 120 | 16 | 3 |

| 59001401 | 14MA | 23 | 15 | 30 | 130 | 16 | 3 |

| 59001601 | 16MA | 25 | 17 | 30 | 150 | 20 | 3 |

| 59001801 | 18MA | 28 | 19 | 35 | 155 | 20 | 3 |

| 59002001 | 20MA | 31 | 21 | 35 | 165 | 20 | 3 |

Involute gear cutters

Involute gear cutters