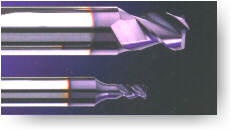

The constant improvement of the powder metallurgy process now gives the possibility to obtain micro fine grain particles smaller than 1 micron.

For small size tools, because of the micrograin carbide characteristics, the machining capability is much more superior than the previous grades offered. This means that we can now offer a better service than before, i.e. delivery and quality, since it is no longer necessary to use different grades such as (K 10, P 25). DIXI 4 micrograin end mills offer high performance machining of most materials.

MillingWith the XIDUR® special multi layer black coated intended for the machining of hard and heat treated steels (HRC30 - 60) complex milling shape and also capable of milling ferrous materials at high speed (HSC) gives the extra endurance and durability.

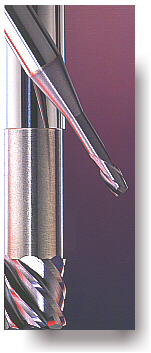

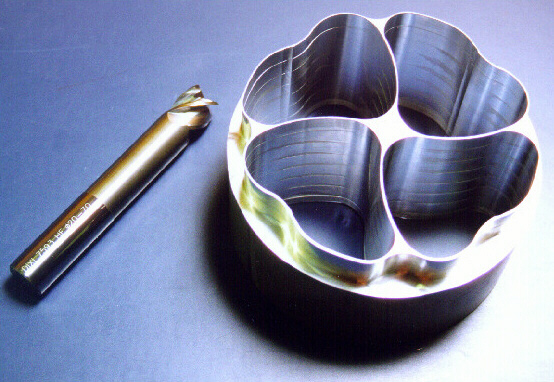

DIXI 7070 HF XIDUR® - Multiteeth corner radius end mills for milling complex shapes

The geometry has been optimized for roughing and semi-finishing operations. The cutters have been designed to machine various materials used by mould makers (steels and cast irons of hardness 30 to 55 HRC).

In opposition to ball nose cutters, corner radius cutters guarantee a nearly constant cutting speed on the complete radius. Therefore phenomenon of wear are reduced and the tools can remove very significant chip volumes.

The advantages of this DIXI 7070 HF:

(metric size)

(metric size)

| D1 (H6) | L1 | D2 | L2 | D (H6) | L | r | Z |

| 3.00 | 4.50 | 2.75 | 12.00 | 6 | 57 | 0.50 | 4 |

| 4.00 | 6.00 | 3.70 | 13.50 | 6 | 57 | 0.50 | 4 |

| 5.00 | 7.50 | 4.60 | 7.50 | 6 | 57 | 0.50 | 4 |

| 6.00 | 9.00 | 5.50 | 24.00 | 6 | 66 | 0.50 | 4 |

| 6.00 | 9.00 | 5.50 | 24.00 | 6 | 66 | 0.80 | 4 |

| 6.00 | 9.00 | 5.50 | 24.00 | 6 | 66 | 1.00 | 4 |

| 6.00 | 9.00 | 5.50 | 24.00 | 6 | 66 | 1.50 | 4 |

| 8.00 | 10.00 | 7.50 | 28.00 | 8 | 75 | 0.50 | 6 |

| 8.00 | 10.00 | 7.50 | 28.00 | 8 | 75 | 1.00 | 6 |

| 8.00 | 10.00 | 7.50 | 28.00 | 8 | 75 | 1.50 | 6 |

| 8.00 | 10.00 | 7.50 | 28.00 | 8 | 75 | 2.00 | 6 |

| 10.00 | 12.00 | 9.25 | 30.00 | 10 | 75 | 0.50 | 6 |

| 10.00 | 12.00 | 9.25 | 30.00 | 10 | 75 | 1.00 | 6 |

| 10.00 | 12.00 | 9.25 | 30.00 | 10 | 75 | 1.50 | 6 |

| 10.00 | 12.00 | 9.25 | 30.00 | 10 | 75 | 2.00 | 6 |

| 10.00 | 12.00 | 9.25 | 30.00 | 10 | 75 | 2.50 | 6 |

| D1 (H6) | L1 | D2 | L2 | D (H6) | L | r | Z |

| 12.00 | 12.00 | 11 | 32.00 | 12 | 83 | 1.00 | 6 |

| 12.00 | 12.00 | 11 | 32.00 | 12 | 83 | 1.50 | 6 |

| 12.00 | 12.00 | 11 | 32.00 | 12 | 83 | 2.00 | 6 |

| 12.00 | 12.00 | 11 | 32.00 | 12 | 83 | 3.00 | 6 |

Designed for the HSC of non ferrous materials, these end mills enable the machining of deep pocket and long reach application, thanks to the superior rigidity of the tool and its shoulder relief behind the cutting diameter. These tools are also available with radii on request.

D2 = D1 - 0.40 mm

D2 = D1 - 0.40 mm

| D1h10 | L1 | Dh6 | L2 | L | Z |

| 6.00 | 6.0 | 6 | 30 | 66 | 3 |

| 8.00 | 8.0 | 8 | 45 | 81 | 3 |

| 10.00 | 10.0 | 10 | 50 | 90 | 3 |

| 12.00 | 15.0 | 12 | 55 | 100 | 3 |

| 16.00 | 16.0 | 16 | 72 | 120 | 3 |

| 20.00 | 20.0 | 20 | 80 | 130 | 4 |

Milling cutter using DIXI 7593 HF Dia. 20 mm

Volume of material removed during roughing operation (Q) = 1800 cm3/min

Total machining times = 9 minutes

| Roughing | Finishing |

| Cutting speed = 880 m/min | Cutting speed = 880 m/min |

| Feed = 10.000 mm/min | Feed = 4.000 mm/min |

| n = 14.000 rpm | n = 14.000 rpm |

| Depth of cut (ap) = 15 mm | Depth of cut (ap) = 15 mm |

| Width of cut (ae) = 5 to 12 mm | Width of cut (ae) = 0.20 mm |

Intended for machining of stainless steels, these XIDUR® multi-coated end mills are capable of reaching very high feed rates and also reduce the development of burrs. For improved wear resistance and performance, especially in tough materials, all tools in the series DIXI 7543 have a chamfer rather than a sharp corner.

| D1h10 | L1 | Dh6 | L | Z | Cutting datas Vc = 200 - 300 m/min |

| 1.00 | 2.0 | 4 | 50 | 3 | |

| 2.00 | 3.0 | 4 | 50 | 3 | |

| 3.00 | 4.5 | 6 | 57 | 3 | |

| 4.00 | 6.0 | 6 | 57 | 3 | |

| 5.00 | 7.0 | 6 | 57 | 3 | |

| 6.00 | 8.0 | 8 | 63 | 3 | |

| 8.00 | 10.0 | 10 | 72 | 3 | |

| 10.00 | 12.0 | 10 | 72 | 3 | |

| 12.00 | 15.0 | 12 | 83 | 3 |