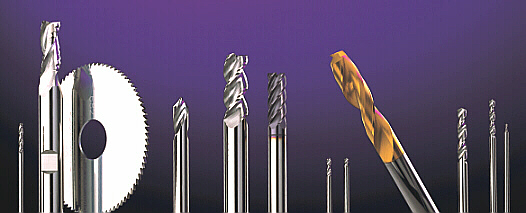

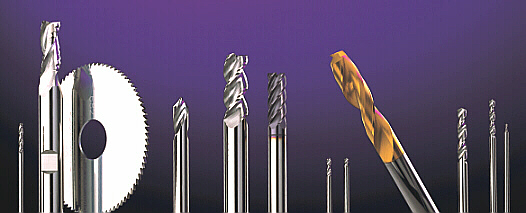

The ultra-modern equipment within DIXI POLYTOOLS gives an idea of the evolution to which they have contributed, having been present from when the possibilities of the industrial employment of tungsten carbide were ensured.

For DIXI, quality is a mentality and an integral part of services, of manufacturing of tools and the material they use. The notion of which everyone takes pride, but for whom only few realize the implications.

The field of miniaturization implies tools of extremely small dimensions destined for micro machining, requiring an outstanding quality of surface finish and manufactured to extreme precision. As to the machining speeds, DIXI are constantly increasing. Responding to these phenomena, DIXI specialize in high speed cutting (HSC) for milling and drilling as well as micro-machining.

Carbide End mills and Ball-nose end mills in 2-3-4-multi flutes, from diameter 0.15 mm up to 20 mm in 0.05 mm increments.

Carbide End mills and Ball-nose end mills in 2-3-4-multi flutes, from diameter 0.15 mm up to 20 mm in 0.05 mm increments.

Complete range of carbide twist drills as DIN 338, DIN 6539, DIN 1899, DIN 6537 from diameter 0.08 mm up to 6.00 mm in 0.01 mm increments, diameter 1.00 mm up to 16.00 mm in 0.10 mm increments.

Complete range of carbide twist drills as DIN 338, DIN 6539, DIN 1899, DIN 6537 from diameter 0.08 mm up to 6.00 mm in 0.01 mm increments, diameter 1.00 mm up to 16.00 mm in 0.10 mm increments.